ACCELERATING BIOGAS PRODUCTION

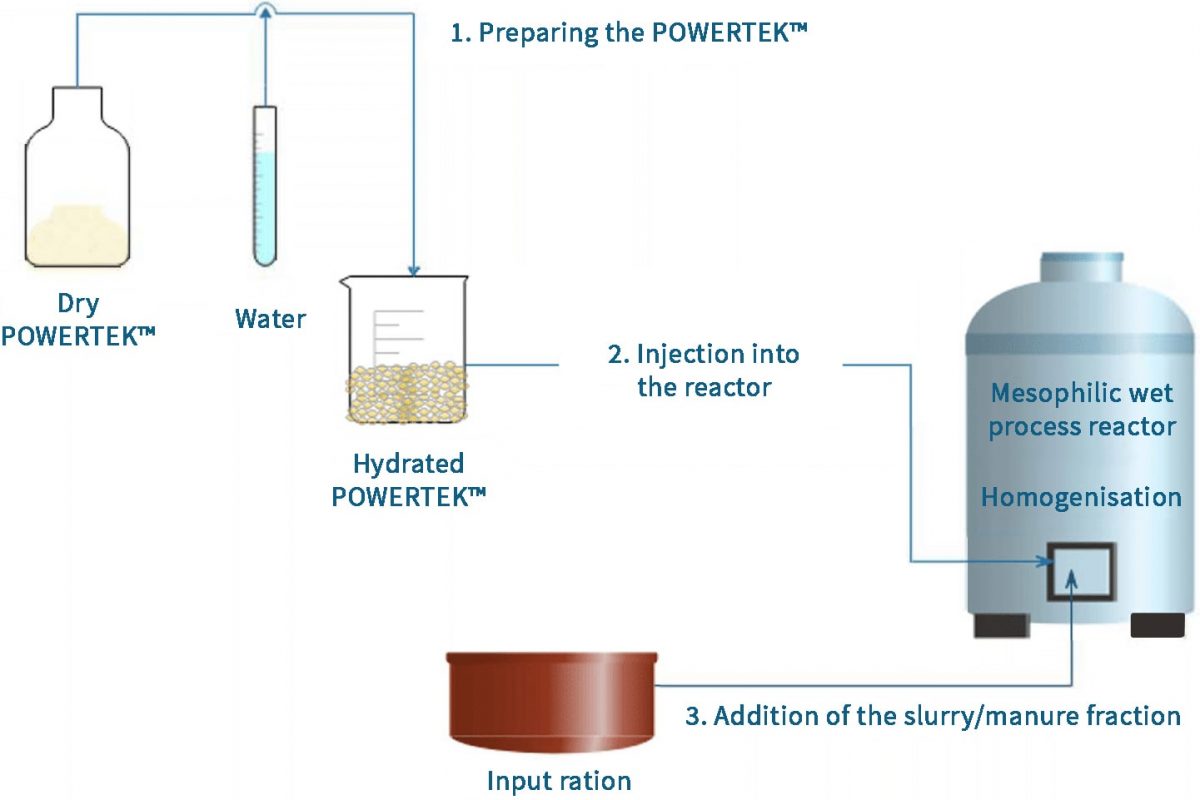

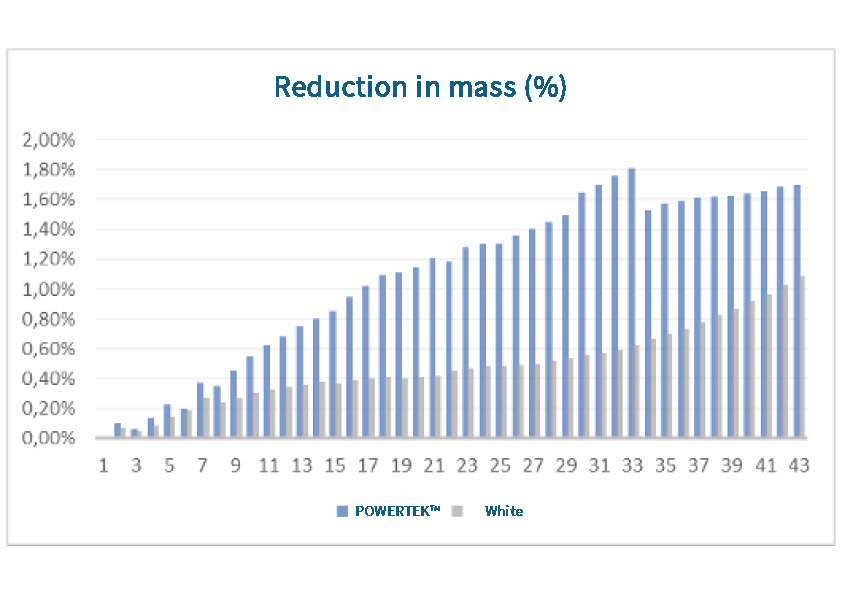

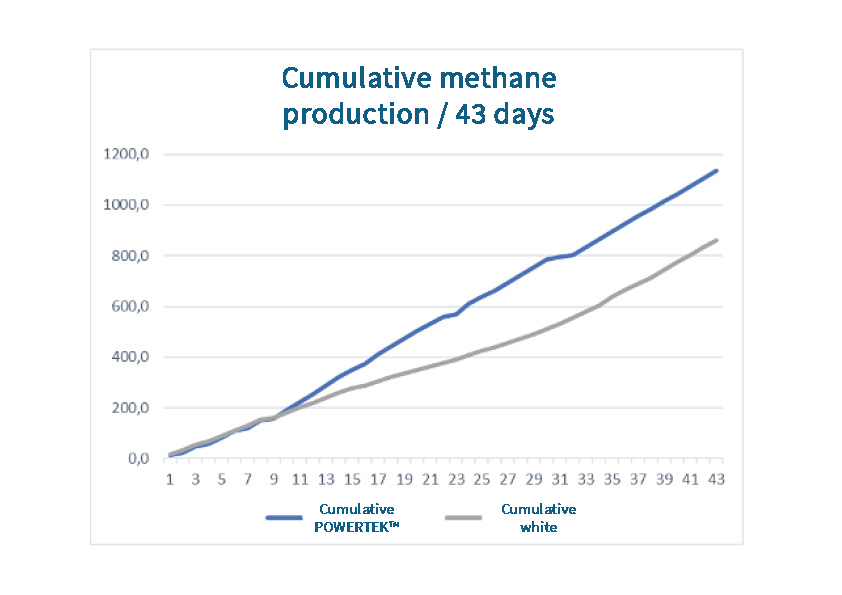

POWERTEK™ is a superabsorbent polymer that effectively and very simply increases the degradation of lignocellulosic residues in digesters during anaerobic fermentations.

POWERTEK™ thus enables higher biogas productions.

FASTER DEGRADATION

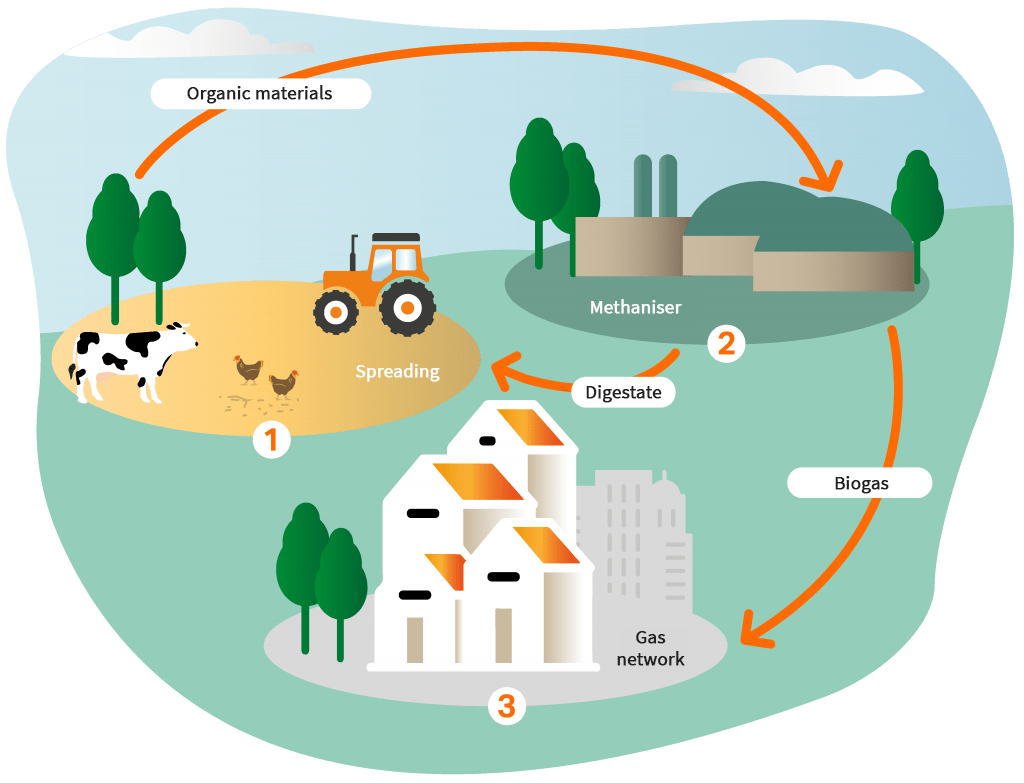

Usually, the organic matter stored in the digester degrades very slowly. In anaerobic digestion, only 40% of the lignocellulosic residues are transformed into biogas. At the end of the process, 60% remains in the digestate.

This patented technology enables operators to make substantial savings while reducing the residence time of materials in the digester.

OPERATION

why choose POWERTEK™?

ACCELERATE

ACCELERATE

RECOVERY

RECOVERY

PERFORMANCE

PERFORMANCE

efficiency

in the digester

efficiency

savings

savings

ecological

ecological

APPLICATION

APPLICATION

INNOVATION

by 2 patent applications

INNOVATION

by 2 patent applications

INCREASE IN LHV

APROMUD® superabsorbent polymers are capable of absorbing and storing more than 100 times their own weight in water.

In the mining sector, they are used to dehumidify coal, thereby improving transport costs, handling and specific energy values.

BETTER COMBUSTION

Thermal degradation of APROMUD® starts at around 204°C and can be accelerated by increasing temperature. The quantity of APROMUD® tested and the rate of temperature rise have a critical influence on the thermal degradation process.

For example, the thermal degradation of 1 g of APROMUD® will take at least two hours at 220°C, whereas it should be completed in a few seconds at over 1000°C.

Complete combustion of this APROMUD® together with other combustible materials such as coal, liquid fuels, solid waste, etc. in a properly functioning incinerator will produce only small quantities of carbon dioxide and water vapour.

APROMUD® is by definition a combustible product, producing approximately 6000 BTU/lb. Once combustion of APROMUD® is complete, only sodium ash remains.

why choose APROMUD®?

LOWER EMISSIONS

LOWER EMISSIONS

performance

of coal

performance

ecological

✓ environmentally friendly

✓ do not produce toxic gases when incinerated

ecological

✓ environmentally friendly

✓ do not produce toxic gases when incinerated

reduction

the amount of waste

reduction

the amount of waste

easy to use

✓ low-cost feeding equipment

easy to use

✓ low-cost feeding equipment